Get high-quality auto detailing to refresh your vehicle’s beauty.

Wiki Article

A Comprehensive Guide to the Kinds of Ceramic Coating on the marketplace

Ceramic coverings have arised as a pivotal option throughout numerous industries due to their special residential or commercial properties and applications. As we discover the unique characteristics and applications of these layers, the implications for performance and durability become increasingly apparent, elevating inquiries concerning which type could best match your requirements.Comprehending Ceramic Coatings

Ceramic layers are advanced safety options that have actually gotten popularity in various industries, particularly in automotive and aerospace applications. These finishings are composed of a liquid polymer that, when treated, develops a sturdy, hydrophobic layer on the surface of the substrate. This layer gives improved resistance to environmental contaminants, UV radiation, and chemical exposure, thereby expanding the life and visual appeal of the underlying product.The essential component of ceramic coatings is silica, which adds to their hardness and longevity. The application process normally entails surface area preparation, application of the coating, and curing, which can be achieved with warmth or UV light. Once healed, ceramic finishings exhibit exceptional bonding homes, allowing them to stick strongly to a selection of surfaces, consisting of metals, plastics, and glass.

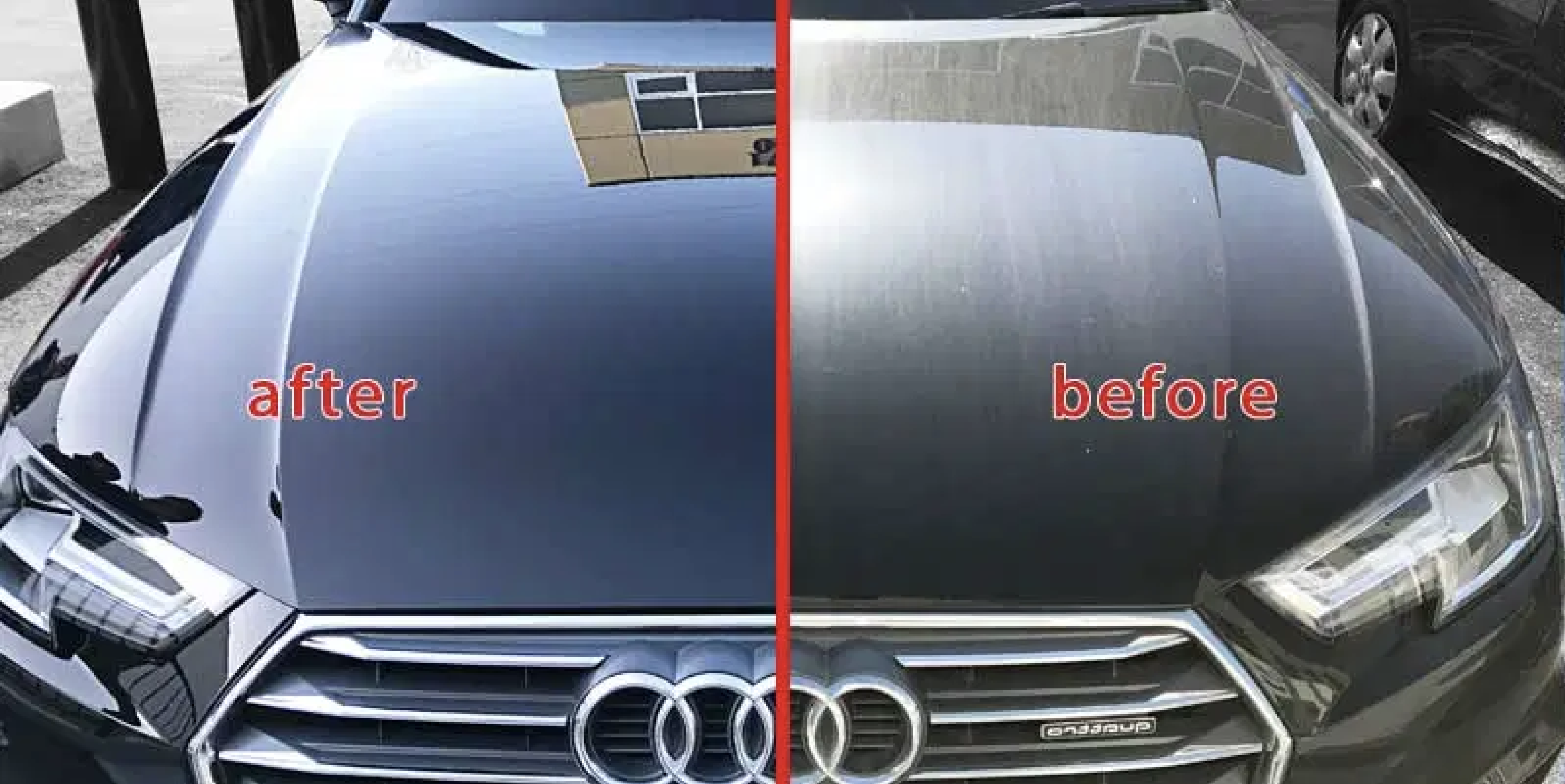

In addition to their safety functions, ceramic coatings additionally provide ease of upkeep. Their hydrophobic nature reduces the adherence of dust and crud, making cleaning less complex and less regular. In general, the fostering of ceramic coverings stands for a significant development in surface security innovation, providing both practical and aesthetic benefits across multiple markets.

Kinds Of Ceramic Coatings

Numerous kinds of ceramic layers are offered, each designed to satisfy certain performance requirements and applications - Auto Detailing. One of the most common types consist of:Silica-based Coatings: These finishes mainly include silicon dioxide and are recognized for their toughness and chemical resistance. They are extensively used in automobile and commercial applications.

Titanium Dioxide Coatings: Popular for their photocatalytic residential or commercial properties, titanium dioxide coatings are commonly used in environments where self-cleaning and antifungal homes are desirable, such as in structure materials and automotive surfaces.

Zirconia Coatings: Characterized by their high-temperature stability and thermal resistance, zirconia finishes are utilized in applications such as generator engines and high-performance automotive components.

Alumina Coatings: Showing outstanding solidity and thermal security, alumina finishings are regularly made use of in wear-resistant applications, including cutting tools and commercial equipment. - Auto Detailing

Hybrid Coatings: Incorporating the residential or commercial properties of numerous products, crossbreed layers use enhanced performance attributes, making them ideal for unique and requiring applications.

Each kind of ceramic coating offers unique purposes, enabling users to choose the most ideal option based on certain environmental conditions and performance demands.

Advantages of Ceramic Coatings

Ceramic finishes, in this page particular, offer numerous advantages that make them increasingly popular amongst suppliers and customers alike. These finishes are immune to scratches, chemicals, and UV rays, guaranteeing that the underlying surface stays safeguarded over time.Along with resilience, ceramic coatings provide exceptional hydrophobic homes, enabling easy cleaning and upkeep. This water-repellent nature decreases the adherence of dirt, gunk, and various other impurities, which can prolong the aesthetic allure and functionality of the surface area. Ceramic finishings can considerably enhance thermal resistance, making them optimal for applications that withstand high temperatures.

Application Process

When using ceramic coatings, a careful strategy is necessary to accomplish optimal results. A clean surface area guarantees correct bond of the finishing.As soon as the surface is prepped, the following step is to apply the ceramic finishing. The layer needs to be applied in slim layers, as thicker applications can lead to uneven finishes.

After application, the layer needs a details treating time, usually varying from a few hours to a full day, depending upon the item. During this time around, it is essential to stay clear of exposure to moisture or contaminants. Finally, a mild buffing might be necessary after healing to enhance the gloss and remove any kind of high spots. Complying with these steps carefully will make best use of the effectiveness and long life of the ceramic finish, offering a long lasting protective layer for the surface.

Maintenance and Longevity

To guarantee the durability and effectiveness of a ceramic coating, normal upkeep is crucial. Ceramic finishes, recognized for their resilience and safety qualities, need particular treatment regimens to maximize their life-span and efficiency. useful source The primary step in maintenance includes routine cleaning with pH-neutral soap, preventing severe chemicals that can deteriorate the covering. It is a good idea to wash the lorry consistently, ideally every 2 weeks, to avoid the buildup of pollutants that can compromise the finish's integrity.Along with normal washing, periodic examinations are critical. Look for indications of wear or damages, such as hydrophobic buildings decreasing or surface area blemishes. If necessary, a light gloss might be put on revitalize the layer without removing it away.

In addition, the application of a booster spray can boost the layer's hydrophobic impacts and restore its gloss. This is particularly useful for finishings that have actually been in use for a prolonged period. Eventually, by adhering to these upkeep techniques, one can substantially prolong the life of a ceramic layer, guaranteeing that it proceeds to give optimum protection against ecological aspects and keep the aesthetic allure of the lorry.

Verdict

Report this wiki page